Electric Stacker

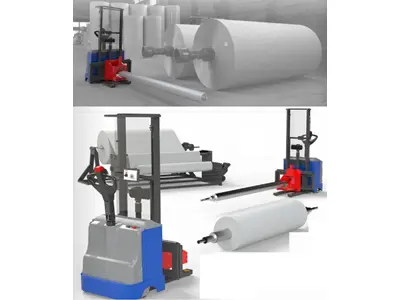

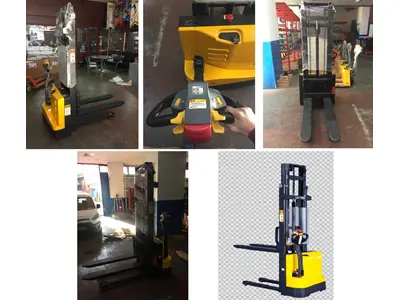

An electric stacker is a material handling and stacking equipment used in storage and logistics industries. It is mainly used to lift, transport, and stack loads inside warehouses. Electric stackers are powered by batteries and operate with electric motors. These machines can have various functions, including fork arms for lifting loads, height-adjustable arms, maneuverability in tight spaces, and the ability to rotate. Electric stackers are used to increase efficiency, reduce labor, and optimize warehouse operations. They are important equipment in the storage and logistics industries due to their efficient performance. These machines have a special structure that operates with electricity and rechargeable batteries. Operators control the machine through a control panel or remote controllers to perform various functions. Electric stackers are designed to lift, transport, and stack loads safely. Their use aims to optimize warehouse operations and increase work efficiency. In addition, electric stackers are equipped with various safety features to ensure operational safety.

Electric stackers are offered with various capacities and lifting heights to be used in different height rack systems. These machines, usually with load carrying capacities ranging from 1 ton to 2.5 tons, stand out with their ability to maneuver easily in tight spaces. With their compact design, they offer high maneuverability even in narrow aisles, ensuring efficient use of warehouse space. Electric stackers, powered by electricity, offer low operating costs. These machines eliminate fuel costs and minimize maintenance requirements. Electric motors have fewer moving parts, reducing the risk of breakdowns and providing long service life. This significantly reduces operating costs and ensures cost-effectiveness in the long run. Another important advantage of electric stackers is their quiet operation. These machines, which keep noise levels to a minimum, are ideal, especially in noise-sensitive working environments or enclosed spaces. Quiet operation provides a more comfortable and safe working environment for both operators and other personnel.

Standing out with their environmentally friendly features, electric stackers offer zero emissions and prevent the emission of harmful gases into the environment. This feature helps businesses fulfill their environmental responsibilities and contribute to sustainability goals. In addition, electric stackers can operate with renewable energy sources, helping businesses reduce their carbon footprint. With its ergonomic design, electric stackers ensure operators work comfortably for long periods. Spacious cabins, easily accessible control panels, and user-friendly interfaces enable operators to perform their tasks more efficiently. Modern electric stackers are also equipped with advanced safety features, enhancing both operator and workplace safety.

Electric Stacker User Manual

Before using an electric stacker, it is important for operators to follow specific instructions to ensure their safety and achieve maximum efficiency.

-

Training: Operators must receive necessary training before using an electric stacker. They need to be trained on how to use the machine, safety measures, and emergency procedures.

-

Inspection of Controls: Before using the machine, ensure that all controls and systems are operational. Check battery levels and recharge if necessary.

-

Load Capacity: It is important not to exceed the specified load capacity of the machine. Determine the weight of the loads to be carried by checking the capacity plate on the machine.

-

Proper Placement of Loads: When carrying loads, it is important to place the fork arms correctly and carry the load evenly. Make sure the loads do not exceed the limits of the fork arms.

-

Speed Control: It is important to move the machine in a controlled manner. Avoid sudden acceleration or sudden stops.

-

Safety: When using the machine, use safety equipment and be attentive to other workers. Follow markings and specific safety procedures.

-

Emergency Procedures: Knowing and implementing designated procedures for emergencies is important. Be prepared for designated procedures for fires, accidents, or other emergencies.

-

Maintenance: It is important to perform basic maintenance procedures before and after using the machine. Check oil levels, check tire pressure, and perform necessary cleaning procedures.

Electric Stacker Prices

The prices of electric stackers can vary depending on the machine's capacity, brand, model, lifting height, battery features, and additional functions. Generally, as the carrying capacity increases and the technological equipment of the stacker improves, prices also rise. Models with basic features and low capacities are offered at more affordable price ranges, while machines with higher capacities and advanced features may have higher price tags. Prices are also related to whether the machine is new or second-hand, warranty period, maintenance services, and spare parts support. Additionally, the capacity and quality of the battery used can significantly affect the price since battery performance directly affects the machine's operating time and efficiency. The average price range for an electric stacker can be {price range}. For more accurate and up-to-date price information on electric stackers, it is recommended to contact manufacturers or suppliers directly through makinaturkiye.com. This way, you can choose the stacker machine that best suits your business needs and budget and get the best price offers.

To meet your needs for new or used electric stacker, you can purchase from reliable manufacturers or authorized suppliers through makinaturkiye.com and also get support from authorized services.