Цифровая машина для печати на футболках 2 / Видео

Aeoon Kyo

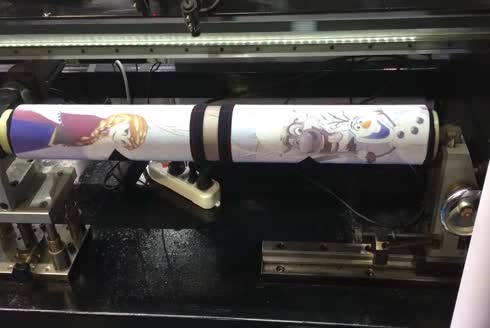

Digital T-Shirt Printing Machine

AEOON , produced in Austria, is the KYO series industrial digital t-shirt printing machine with the fastest production capacity on the market. With AEOON, KYO series digital t-shirt printing machine, printing directly on the fabric can go up to 1280 pieces per hour on white t-shirts. In addition, all AEOON digital printing machines are designed so that the number of print heads (speed) and pallet sizes (printing area) can be customized. KYO series, which makes mass production using 3 pallets (t-shirt laying area), provides the opportunity to print on large areas using a single large pallet as needed. Therefore, it meets your high production needs at the industrial level in the most appropriate way for your use.

The KYO 8 model digital t-shirt printing machine has 8 print heads, but you can greatly increase its speed by adding 4 more print heads whenever you want.

When used with “CMYK + 4 White” 8 print head setup, it has the capacity to produce 350 A4 sized patterns per hour on dark backgrounds and 800 pieces per hour on white backgrounds.

When used with the “CMYK + CMYK” 8 print head setup, it can only print on white backgrounds and has the capacity to produce 1280 A4 sized patterns per hour .

KYO 12 model digital t-shirt printing machine has 12 print heads and is the model with the fastest production capacity.

When used with “CMYK + 8 White” 12 print head setup, it has the capacity to produce 510 A4 sized patterns per hour on dark backgrounds and 800 pieces per hour on white backgrounds.

When used with “CMYK + CMYK + 4 White” 12 print head setup, it has the capacity to produce 350 A4 sized patterns per hour on dark backgrounds and 1280 pieces per hour on white backgrounds.

How is Digital Printing Done?

Digital printing machines can print your patterns by transferring them directly from the computer onto all substrates (cotton, polyester, linen, wool, silk, denim, leather, etc.). Digital printing machines produce images containing countless colors prepared in various graphic software (Photoshop, Illustrator, etc.); It transfers up to 16 million colors on various surfaces using 4 main colors "C+M+Y+K, Cyan+Magenta+Yellow+Black, Cyan+Magenta+Yellow+Black".

Although you have a color limit in screen printing, pre-printing processes such as emulsion drawing, film pattern settings, mold preparation, exposure and washing, which are mandatory for printing, are not available in digital printing. Therefore, you can prepare your designs in various graphic software (Photoshop, Illustrator, etc.) and print directly on various surfaces. Compared to screen printing, you save time and labor and eliminate preliminary preparation costs. While digital printing is used for high production purposes, it is also active in areas such as personalized designs and e-commerce t-shirt sites.