Dijital Çorap Baskı - 4 Çorap Üzerine Aynı Anda! Beyaz Çorap ile Sınırsız Renk! (2) 2 / Video

İnk Epson Dx7

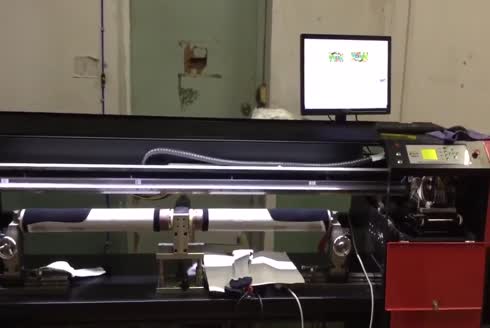

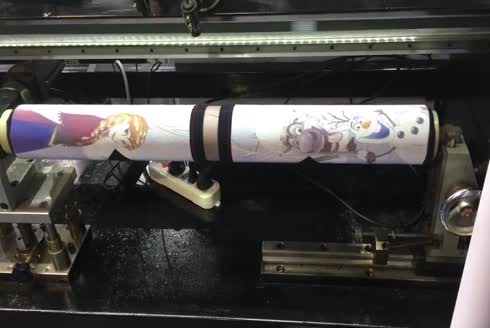

Digital Socks Printing Machine

New technology digital sock printing machine; cotton, polyester, silk, wool etc. It is produced to perform full circle digital printing on all socks and for various sizes (short, long, adult, baby) . The new generation digital sock printing machine, which eliminates the expensive jacquard machines, high jacquard production costs and yarn residues needed for multi-colored socks production, requires only white socks for production and digitally transfers your designs containing hundreds of colors onto your socks without edge joining marks . It has a production capacity of 60 Pairs/Hour (120 Pieces) to cover every surface of the socks on white socks with EPSON DX7 print heads, using high-resolution images prepared in various graphic software (Photoshop, Illustrator, etc.) without any color and design limits. On the other hand, the roll sock placement chamber technology, which allows four or six socks to be put on and taken off at the same time, provides an easy/fast sock putting on and taking off process, as well as the opportunity to print on four or six socks at a time . By ordering more of the removable sock placement chamber, the 2nd placing chamber can be prepared while the printing continues, thus more mass production can be achieved.

How is Digital Printing Done?

Digital printing machines can print your patterns by transferring them directly from the computer onto all substrates (cotton, polyester, linen, wool, silk, denim, leather, etc.). Digital printing machines produce images containing countless colors prepared in various graphic software (Photoshop, Illustrator, etc.); It transfers up to 16 million colors on various surfaces using 4 main colors "C+M+Y+K, Cyan+Magenta+Yellow+Black, Cyan+Magenta+Yellow+Black".

Although you have a color limit in screen printing, pre-printing processes such as emulsion drawing, film pattern settings, mold preparation, exposure and washing, which are mandatory for printing, are not available in digital printing. Therefore, you can prepare your designs in various graphic software (Photoshop, Illustrator, etc.) and print directly on various surfaces. Compared to screen printing, you save time and labor and eliminate preliminary preparation costs. While digital printing is used for high production purposes, it is also active in areas such as personalized designs and e-commerce t-shirt sites.