(2) 2 / Video

FGM Otomasyon Makina İmalati San. Ve Tic. Ltd. Şti.

tarafından 30.12.2023 tarihinde eklendi.

Automatic Liquid Filling and Capping Machine

The Liquid Filling and Capping Machine is an industrial equipment that automates the filling and capping processes of liquid products in production. The liquid filling machine enables the automatic filling and capping of various liquid products used across industries such as Olive Oil, Liquid Soap, Dish Detergent, Shampoo, Body Lotions, Cleaning Products, Cosmetic Items, and Chemical Substances.

Key Features and Advantages of the Liquid Filling and Capping Machine:

Automatic Process: This machine fully automates the Liquid Filling and Capping processes, reducing human intervention, increasing process speed, and ensuring consistency.

Flexibility: It can be designed to accommodate filling and capping for different sizes of bottles and caps, providing manufacturers with the flexibility to produce various products.

Fast and Precise Filling: The machine ensures rapid and precise filling, leading to time and material savings during the production process.

Capping: Following the liquid filling process, the machine performs automatic capping, completing the packaging process.

Hygiene and Safety: The machine conducts filling and capping operations for liquids in hygienic conditions, enhancing product quality. Additionally, it may have safety measures designed to ensure operator safety.

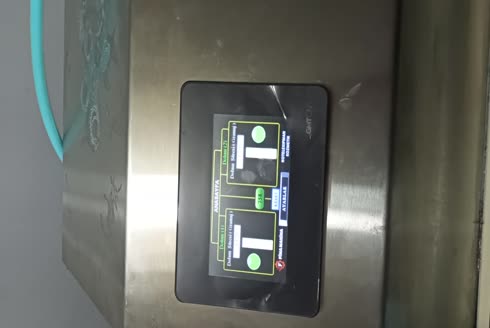

Ease of Use and Adjustment: Featuring a user-friendly interface, it makes it easier for operators to effectively use and adjust the machine.

Increased Efficiency: Automation with the Liquid Filling and Capping machine increases production speed and reduces operational costs, thus enhancing production efficiency.

Tracking and Reporting: Some models can record data and generate reports for tracking the filling and capping operations, aiding better management of the production process.

Durability and Longevity: Machines manufactured with quality materials, often utilizing 304 and 316 stainless steel, provide long-term service.

Cost-effective Solution: Efficiency gains from automation and savings in labor costs rapidly offset the machine's initial cost.

This machine serves as a robust industrial equipment performing Liquid Filling and Capping operations swiftly, efficiently, and accurately. It provides lasting solutions for manufacturers to enhance product quality and advance production processes with precise and rapid planning.

Industries We Serve:

-

Food Industry: Offering serial production solutions in food industries like Olive Oil, Sunflower Oil, Vinegar, Lemonade, Fruit Juices, Tomato Paste, Ketchup, Mayonnaise, Molasses, Tahini, Sauces, Non-carbonated liquid filling, and various types of caps and labeling requirements.

-

Cosmetics, Personal Care, and Cleaning Products: Providing serial production solutions for wax filling, hair gel filling, waxing products, hair styling products, body lotions, and trigger cap closing machines, pump valve closing machines, screw cap machines, flip-top cap machines, push-pull cap machines, and labeling machines tailored to specific product needs.

-

Pharmaceuticals (Human and Agricultural): Offering solutions for liquid product filling like syrup, nasal spray, mouthwash, spray cap sealing machines, screw cap sealing machines, and labeling machines specific to the pharmaceutical industry.

-

Chemical Industry: Providing solutions for liquid filling machines for chemical products like agricultural chemicals, liquid fertilizers, cleaning solutions, thinner, detergents, disinfectants, ink, and custom labeling machines tailored to the chemical industry's serial production needs.

Technical Specifications

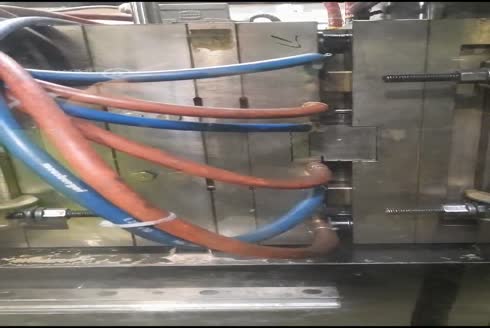

- Filling Group: 304 quality stainless steel Sealing Elements:

- PTFE TEFLON and VITON Control Systems: Touch Screen and Electro Pneumatic (LG brand PLC and LG 10-inch touch screen + Pemaks pneumatic) TURKISH-ENGLISH LANGUAGE OPTIONS

- Preventative: Bottom and top filling nozzle system for foaming products (8-HEAD) can be produced upon request.

- Filling System: LG Servo + Pemaks Pneumatic

- Filling Volume: 100 ML - 1000 ML

- Filling Capacity: 3000 units / hour

- Control Voltage: 24 VDC

- Operating Voltage: 380 V 50 Hz 10A

- Energy Consumption: 4 kW/h

- Dimensions: h 2200 mm x 1200 x 1000 x 3000 mm

- Conveyor: (3-meter Asetal pallet)

- Protection Cabins: Plexiglass coating on 304 quality chassis (for filling and capping)

- CAP CLOSING (CAP SCREWING)

- Chassis: 304 Quality stainless steel

- Conveyor Pallet: (3-meter Asetal pallet)

- Conveyor motor 380 V 0.37 kW (S40 / 21)

- Energy Consumption: 1 kW/h

- Cap Tightening: Torque-controlled screw cap tightening

- Dimensions: h 1800 mm x 1000 x 1000 x 3000 mm