ST 550 Valve Grinding Machine / Video

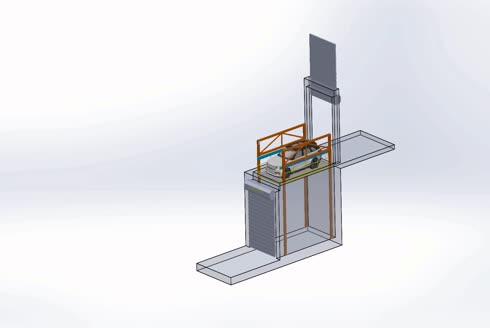

Valve Grinding Machine

The Wespy ST-550 Valve Grinding Machine is a high-performance tool designed specifically for precision valve angle grinding during the overhaul stage of engine maintenance. This machine is essential for restoring the functionality and sealing ability of the valves on cylinder heads, ensuring optimal engine performance after servicing.

Precision Valve Angle Grinding: The ST-550 provides precise grinding of valve angles, ensuring perfect seating and sealing of the valve to the cylinder head. The precision grinding helps in achieving an airtight seal, which is crucial for engine efficiency.

High-Speed Grinding: With its powerful motor and high-speed grinding capabilities, the ST-550 can quickly and efficiently grind a variety of valve sizes, reducing downtime during engine maintenance.

Adjustable Grinding Angles: The machine offers adjustable angle settings, making it versatile for different types of valves, including intake and exhaust valves. This flexibility allows for accurate adjustments based on the specific requirements of each engine type.

Ergonomic Design and Easy Operation: The ST-550 is designed with user comfort in mind, featuring easy-to-use controls, an adjustable work table, and a stable, ergonomic setup. It’s easy to set up, operate, and maintain, making it suitable for both professional mechanics and workshop technicians.

Durable Construction: Built with high-quality materials, the Wespy ST-550 is durable and designed to withstand the rigors of frequent use in a busy workshop environment. The machine’s robust construction ensures consistent, long-lasting performance.

Efficient Cooling System: The integrated cooling system prevents overheating during extended grinding sessions, ensuring the valve surfaces remain smooth and undamaged. This helps to preserve both the valves and the machine itself.

Compact and Space-Saving: Despite its powerful performance, the ST-550 is compact, making it easy to integrate into workshops with limited space. Its streamlined design ensures it doesn’t take up unnecessary room while still providing excellent grinding results.

Improved Engine Efficiency: By ensuring proper valve sealing and seating, the ST-550 helps restore engine compression, which improves overall engine performance and fuel efficiency.

Reduced Maintenance Time: The ST-550 allows for faster and more efficient valve grinding, reducing the time needed for engine overhauls and increasing workshop productivity.

Extended Valve Life: By ensuring accurate valve grinding, the ST-550 extends the life of valves and other engine components, reducing the need for frequent replacements.

Cost-Effective: The machine’s reliability and durability reduce the cost of maintenance and repairs over time, making it a wise investment for any workshop that handles engine overhauls.

Versatility: Suitable for a wide range of engine types, the ST-550 is ideal for both small and large-scale engine servicing, including automotive, industrial, and marine engines.

Automotive Workshops: Ideal for grinding intake and exhaust valves in car, truck, and motorcycle engines during overhauls and repairs.

Industrial Engine Maintenance: Perfect for valve grinding on industrial machinery, generators, and large-scale engines, ensuring proper sealing and efficient operation.

Marine Engines: Used for servicing valves on marine engines, the ST-550 ensures long-lasting performance even in harsh environments.

Heavy Machinery Maintenance: Effective for valve grinding on construction equipment, mining vehicles, and other heavy-duty machinery, improving engine longevity and performance.

The Wespy ST-550 Valve Grinding Machine is a powerful, efficient, and versatile tool for performing high-precision valve grinding. Its adjustable features, durable construction, and efficient operation make it an indispensable machine for engine overhauls, ensuring optimal engine performance and extending the life of vital components.