What is Wire Erosion Machine

With the advancement of technology, machines have taken the place of human strength in many aspects of human life. Wire erosion machine is among the machines that have found a place in human life by being used by many factories and companies. These machines provide precision in many aspects and increase the usage capacities of products. Wire erosion machine, which falls into the dangerous machines group in terms of workplace safety, is only suitable for use by experts who have received proper training. A wrong move can cause harm to people. When machines with automatic operation principle are used, time and quantity adjustments are made. Individuals should only approach the machine to check it occasionally and shut it off suddenly in case of emergency situations. In addition, trying to monitor the machine can lead to negative consequences in terms of human life. People who use advanced technology wire erosion machines should learn automatic operation principles and should not be inside the machine's working area except in emergency situations.

What is Wire Erosion? What is it Used For? Wire Erosion Working Principle

A widely used device in factories and large companies, wire erosion has led people to frequently ask questions such as what wire erosion is. Wire erosion can be evaluated as an electrothermal cutting machine in the simplest terms. This machine, which carries out electro thermal cutting process, involves disintegrating the electric discharges between two electrodes using the abrasive function of the machine on the material. The use of these machines is crucial for cutting erosion wires without damage and making them ready for reuse. Therefore, it will be beneficial to obtain detailed information about the working principle of wire erosion.

In order for electro thermals to be easily used in new productions, they need to be shaped appropriately without losing their characteristics. This process, previously done manually, has led to the production of faulty products and caused malfunctions. Wire erosion, which is involved in human life in ways people are not even aware of, can be cut flawlessly and fully within these devices. Therefore, production is provided without interruption, and high-quality products are produced without problems occurring later.

Electrodes separated perfectly by the wire erosion machine are immersed in liquid inside parts to create a set of electrodes and regain conductivity. The set electrode is processed with the help of a wire. It should be noted that each product has different processing methods. Hard and complex profiles can regain their old form by being processed within high precision devices. An important detail that seems simple is the importance of choosing devices according to the products processed by companies.

The wire erosion machine has a certain operating speed. Those who want a fast operation will definitely need the best machines. However, the conductivity of the processed workpiece also plays an important role in this regard. Speed increases or decreases according to conductivity and hardness. The speed of the device can be increased based on the current intensity, but using high current intensity will cause wire breakages and damage to the workpiece. Those who want to produce quality products should not raise the current intensity above a certain level. In addition, those who expect higher speed should benefit from higher quality machines.

Types of Wire Erosion Machine

Wire erosion machines have different working principles and features. Therefore, machines with different working principles should be used according to the properties of the processed part. Individuals who want to set up a wire erosion machine should be knowledgeable about the product they are working on. However, if they do not have information about which machine will be the best, it will be useful to consult with someone who knows about the job.

- Agie Wire Erosion Machine: Among the reliable brands that individuals can benefit from, Agie wire erosion is very practical and high quality. It is reliably procured, and individuals can use the same machine for many years.

- Makino Wire Erosion: It is also one of the reliable brands. Makino wire erosion is among the most preferred models with an affordable price guarantee.

- CNC Wire Erosion: CNC wire erosion machine is the type of erosion machine preferred by factories and large companies. Most of those who set up CNC wire erosion machines leave the service very satisfied. CNC wire erosion does not require coil changes every time. It has an affordable price and excellent performance guarantee. It provides usage security even for materials with very high electrical conductivity. The individuals can benefit from this model, which they can obtain with peace of mind, is very useful and practical models. The materials that can be used in the CNC wire erosion machine are as follows.

- Graphite material,

- Carbur material,

- Pure molybdenum material,

- Flat plate materials containing very crystalline alloys,

- Every material with electrical conductivity is suitable for use in this machine. The abundance of options helps individuals create a more comfortable usage area. This situation has placed this machine at the top of the most preferred products.

Wire Erosion Machine Prices

It varies according to the type and brand of the product to be purchased. In the booth where different products are available, individuals have the chance to determine the most suitable option for themselves. Firstly, they need to be informed about the electrical conductivity of the product they use. It should not be forgotten that machines to be used for materials with very high conductivity are the highest quality products. If individuals work with very high conductivity materials from time to time and mostly process medium conductivity and thickness materials, they can buy a machine of medium standard. The price of a wire erosion machine is among the machines that need to be carefully selected, because the prices of these products are high, and efforts are made to make them suitable for continuous use.

Newly established workplaces can benefit from manual wire erosion devices. There is no need to be careful about choosing a very good brand in the first place, and individuals can renew their machines as their business grows. There is no need to make very high expenses suddenly without seeing the power of production and turnover. Correct choices can be made over time by looking at the course of the situation. If a machine for high conductivity and hardness materials is necessary, individuals can benefit from machines that are not very good brands and do not have very high production capacities in this case. A new workplace that will produce products with high conductivity and hardness and does not have enough budget should benefit from second-hand quality products. Most of the second-hand products are lightly used and products with very high operating capacity. Therefore, individuals must take advantage of the opportunities provided by these products. It should not be forgotten that everyone can buy a machine within their means and not incur debts by buying high-priced products suddenly.

Machinery Turkey and Wire Erosion

The Machinery Turkey portal, one of the most reliable companies that individuals can choose to buy machinery, has all the products individuals need. Companies can find different brand and capacity options for the products they want in our company. There are dozens of products in the wire erosion category. If individuals cannot decide which one of these products is the best and cannot make a choice, they must definitely apply to our company to make the right choice. Our company will be very helpful in determining which are the correct product options and will provide continuous support to individuals.

All products in our company, which operates with customer satisfaction focus, are high-quality products suitable for wire erosion cutting for many years. Therefore, whether they buy second hand or new products, individuals will be able to use them for wire erosion for many years. The crucial point here is that individuals should not forget that one important point is to have their products cleaned and maintained regularly. If individuals take good care of their products, the machines will not cause any malfunctions for a long time.

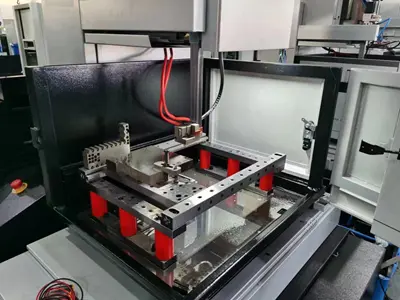

CNC Wire Erosion Machine

In the operations intended to be carried out with wire erosion, wire erosion is operated by computer-controlled, digitally controlled (CNC) machines that can control wire erosion in a three-dimensional axis. Simple cuts are made by changing the cutter's xy coordinates with additional motion axes to wire guides to obtain more complex cuts. In short, CNC wire erosion machines are computer-controlled machines that facilitate more accurate and complex work on the workpiece where erosion is intended.