With their easy and practical uses, stretch wrapping machine varieties create a great convenience for businesses. Businesses achieve significant gains in their operations with stretch wrapping machine varieties while also benefiting from easy-to-use features, making stretching processes easier. You can find the most suitable machines for your business among the models with different features presented on the page.

Fast and Practical Stretch Wrapping Machine Models

With affordable stretch wrapping machine prices, stretching processes become much easier for businesses. The models presented on the page with different features make stretching processes faster while also contributing to lightening the workload of businesses. All machines with different features provide fast and stable operation, meeting the need in the best way possible. Thus, whether automatic or manual stretch wrapping machine is chosen, the selection of machines with the best features always becomes easier.

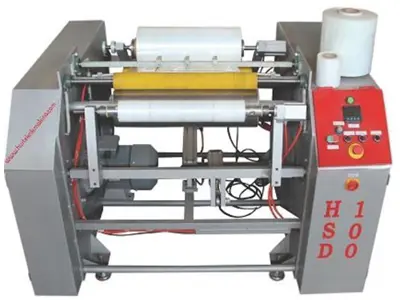

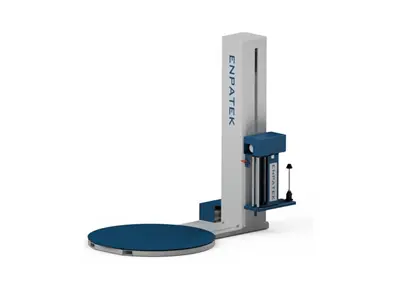

The machines called stretch wrapping machines are machines that wrap pallet top loads with stretch film. In this context, the products produced can be transported in a healthy manner, and at the same time, stretch wrapping machines are of great importance to ensure the protection of products to be stored in the warehouse. Whichever model of stretch wrapping machines is chosen, they always meet the need correctly. Models with motorized pre-stretch or top-yoke stretch versions according to stretch technology structures also have models with battery-powered or mobile capabilities. Thus, with machines that can move to different areas, stretch wrapping processes become faster.

Things to Consider When Choosing a Stretch Wrapping Machine

Certain points should be kept in mind when choosing stretch wrapping machines. The wrapping capacities of models to be chosen according to the operation and workload vary, and another point is the investment cost and, in addition, the daily wrapped pallet quantity. Especially these two points also determine the machines' payback periods. Other factors should be taken into account in determining the investment costs of the machines. Also, since the amount of savings to be made according to the technology of the machine may vary, care should be taken when calculating the payback. Since the stretch wrapping machine is basically a wrapping and packaging machine, keeping the business volume in mind correctly will affect the correct choice of the machine. Stretch wrapping machines, which prevent both the dispersion of products placed on transport pallets and any damage, are extremely important for businesses in this respect. Pallet stretch wrapping machine varieties wrap products directly onto the pallet and thus make them ready for transport. Not only for transportation but also pallet stretch wrapping machine varieties prevent the products from being damaged when they are stored in the warehouse.

How Do Stretch Wrapping Machines Work?

Stretch wrapping machines or stretch transfer machine varieties work within a certain procedure. Firstly, the stretch wrapping machine is mounted on the back of the output conveyor on the palletizing line. The pallet coming out of the output conveyor is automatically taken inside. The pallet taken inside is started to be wrapped from the bottom. The wrapping process starting from the bottom continues to the top and then goes back to the bottom. When the wrapping process is completed, the stretch is held with an automatic holding mechanism and then applied. The remaining part on the pallet is also cut, and the wrapping process of the products is completed. This process is valid for automatic machines, while in manual systems, the user needs to intervene in the wrapping process. Therefore, when choosing from the machines presented on the page, paying attention to the workload and the number of users will be useful. Automatic machines make it easier to carry out the process, while in terms of price, they can be more expensive than manual models.

Always High-Quality Models

The prices of manual and automatic stretch wrapping machines vary according to their features. In order to find the right machine you need, it is necessary to consider the prices, so you can easily compare prices on the page. In this way, you will be able to reach models that will meet your needs correctly and also see the sales figures directly without requiring membership, helping you to get an idea about the sales prices.

In addition to prices, it is important to decide for what purpose you will use the stretch wrapping machine. Machines used for products on pallets are also used for wrapping suitcases or boxes, and there may be model differences for such wraps. However, whichever machine you choose, it always consists of high-quality models, thus extending the service life of the machine you choose.

To make the right choice, you can pay attention to pallet sizes, types, weights, product features, and consider the production environment of the product; factors such as temperature, loading, unloading, and types of packaging materials should be considered. Packaging processes without machines are time-consuming processes, so with the stretch wrapping machine you choose, you will have a great convenience in your business.

For Those Who Want to Wrap Suitcases and Boxes

Suitcase stretch wrapping machine and box stretch wrapping machine varieties, as understood from their names, are used in wrapping the luggage and boxes. Suitcase stretch wrapping machines are also known as suitcase packaging machines, luggage wrapping machines. It is extremely important for places such as hotels, cargo companies, terminals, airports to do suitcase wrapping. In such businesses, the necessary machines for wrapping customers' suitcases or boxes can be purchased by choosing from the different models presented on the page. These models, which will help keep suitcases or boxes protected, basically have a working principle similar to pallet wrapping machines and always provide fast and stable results.

Important Points When Using Stretch Wrapping Machine

For those who will choose stretch wrapping machine, the question of how to use a stretch wrapping machine is important. Basically, stretch wrapping machines are classified as manual, semi-automatic, and fully automatic. In manual stretch wrapping machines, the operation is carried out by staff, and the machine does not work without the personnel. Products are placed in the wrapping part of the machine, and the wrapping process is done by the staff. Semi-automatic models wrap the products automatically, but personnel intervention is required to apply the stretch to the product or the entire pallet.

Automatic stretch wrapping machines work completely automatically in the wrapping processes of the products from start to finish without requiring personnel. Thus, the wrapping processes are completed much easier and faster, and the speed of the processes is increased.

No matter which model of machine you choose, with easy-to-use features, you can find the model that will meet your needs most accurately on the page, thus providing an important convenience for your business.