Medicine Mixing Machine kategorisinde ürün bulunamadı.

Benzer kategorideki diğer ilanlar listelenmektedir.Drug Machines

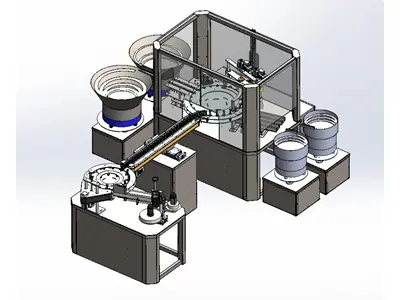

Drug machines are special equipment used in the drug sector for the production, processing, and packaging of different types of drugs. These machines are designed to meet the high hygiene and quality standards of the drug industry.

These machines provide quality, speed, and efficiency at every stage of the drug production process, and drug machines are of critical importance for the proper selection of machines to optimize drug production.

Drug production machines are complex industrial equipment that allows drugs to be produced in different forms and quantities. The working principles of these machines vary according to the different types of drugs and the stages of production they are used in.

What Are the Types of Drug Machines?

1. Tablet Machines: Tablet machines are one of the fundamental machines in drug production. These machines compress the drug raw material into a specific mold and produce drugs in tablet form. The raw material is first placed in the hopper and then measured through the dosing unit. Then, the raw material is directed to the molds and the compression mechanism comes into play. The machine compresses the powdered or granular drug raw material into tablet form by applying pressure. Tablets can come in various sizes and shapes. Tablet machines generally have high production speeds and support precise dosing. The production process can be monitored and adjusted when needed with automatic control systems.

2. Capsule Filling Machines: Capsule filling machines fill powders, granules, or liquid form drugs into capsules. First, empty capsules are fed into the machine and separated. Then, the drug raw material is brought to the filling area and filled with a precise dose for each capsule. Then the capsules are closed and directed to the output section. Capsule filling machines operate at high precision and speed. They adapt to different capsule sizes and perform automatic filling and closing operations.

3. Ampoule and Bottle Filling Machines: These machines perform the filling of liquid drugs into ampoules or bottles. They are used especially when liquid drugs need to be filled with precision. Ampoules or bottles are fed into the machine and undergo a sterilization process. Then, the liquid drug is transferred from the reservoir to the filling area and transferred to the containers with precise measurements. After filling, the containers are sealed. Ampoule and bottle filling machines make precise filling measurements and operate in a sterile working environment. The sealing process is also performed automatically.

4. Packaging Machines: Packaging machines are used to place drugs in various types of packaging such as blister packs, bottles, or boxes and seal them. Drugs are fed into the machine and packaged according to different packaging types. In blister packs, each drug compartment is sealed precisely. In bottles, drugs are automatically filled and capped. Packaging machines perform automatic feeding and packaging at high speed. They adapt to various types of packaging and perform sealing operations automatically.

5. Coating Machines: Coating machines are used to apply coating to the surface of tablets or capsules. Coating is done to enhance the taste of drugs or protect them from stomach acid. Tablets or capsules are fed into the machine and coated with a coating solution. During this process, the tablets or capsules are rotated at a specific speed to come into contact with the coating solution. In the final stage, the coated products are subjected to a drying process. Coating machines provide coating thickness control and work with different coating solutions. The drying stage ensures that the coating is applied uniformly.

6. Mixing and Homogenization Machines: These machines mix drug components to obtain a homogeneous mixture. They are used in the production of syrups, creams, or powder drugs. Drug components are fed into the machine and mixed at certain speeds and durations. Mixers work at different speeds to ensure that the components are thoroughly mixed. Mixing and homogenization machines ensure that the components obtain a homogeneous mixture. They offer flexibility with interchangeable mixing speeds and wide capacity options.

7. Sterilization Machines: Sterilization machines are used to ensure the sterilization of drugs and production equipment. Autoclaves or sterilization rooms are usually available. The products to be sterilized are placed in the machine and exposed to high temperature or chemical sterilization. Autoclaves sterilize using pressurized steam. These machines provide complete sterilization and operate with high-temperature or chemical control.

8. Granulation Machines: Granulation machines convert powdered drugs into granules. Granules are used for tablet or capsule production. The raw material is brought to a specific humidity level and shaped. The machine compresses the drug in powder form and turns it into granules. Granulation machines provide granule size control and are compatible with various shaping types.

9. Scaling and Filling Machines: Scaling and filling machines ensure the packaging of powdered and granular drugs in precise doses. The raw material is fed into the machine and the measurement mechanism makes accurate measurements. Then it is automatically filled into the packages. They make precise measurements and perform fast filling.

10. Labeling Machines: Labeling machines are used to apply labels to drug packages. The products are fed into the machine and the label is applied in the correct position. They adapt to different product sizes and perform fast labeling.

How to Increase the Efficiency of Drug Production Machines?

To increase the efficiency of drug production machines is necessary to achieve higher production capacity, lower costs, and higher quality.

- Regular Maintenance and Repair: Regular maintenance is essential to extend the life of the machine and prevent breakdowns. Follow the maintenance schedule recommended by the machine manufacturer. Keep spare parts ready for unexpected breakdowns.

- Trained Personnel: Well-trained personnel are critical to machine efficiency. Take advantage of the training provided by machine manufacturers. Conduct regular training to keep staff skills up to date.

- Technological Investments: Automation and technological advancements can increase efficiency. Use automatic control systems in production processes. Monitor machines in real-time and analyze data.

- Process Optimization: By optimizing production processes, you can increase machine efficiency. Identify bottlenecks by analyzing the production process. Implement productivity-enhancing techniques such as Lean, Six Sigma.

- Quality Control and Monitoring: Continuously monitoring production quality reduces defective production. Clearly define production standards and requirements. Regularly report and analyze production data.

- Collaboration and Feedback: Feedback from manufacturers and staff enables continuous improvement. Take advantage of technical support from machine manufacturers. Consider feedback from operators and maintenance personnel.

What Are the Prices of Drug Machines?

The cost of drug production machines varies widely depending on various factors such as machine type, capacity, automation level, manufacturer, and additional features. Drug machines can be priced at an average of {price range}. Drug machines should be sourced from reputable suppliers and manufacturers to provide reliable and quality equipment.

- Machine Type: The cost of drug production machines varies widely depending on the specific functions of each machine type. Different types such as tablet machines, ampoule filling machines, and granulation machines have different costs depending on the complexity of production processes.

- Automation Level: Fully automatic drug production machines are generally more expensive as they provide faster and more efficient production. These machines increase production speed, reducing labor costs. Semi-automatic or manual machines are generally more affordable compared to automatic counterparts.

- Capacity: The production capacity of the machine has a significant impact on the price. Machines with high capacity are more expensive due to their larger and more complex designs. For example, machines that can produce thousands of units per hour are generally more expensive than machines with lower capacity.

- Brand and Manufacturer: The brand and manufacturer of the machine play an important role in pricing. Prestigious and well-known brands offer products with advanced technology and therefore demand higher prices. Technological innovations, quality control standards, and the reputation of the manufacturer can increase the cost of the machine.

- Additional Features: Special features added to the machine and customization requests can affect the cost. For example, machines with automatic cleaning systems, advanced control software, or capable of meeting special production requirements are more expensive than standard models.

- New vs. Second Hand: Second-hand drug production machines may be more affordable, but maintenance and repair costs should be taken into account. New machines generally have a higher initial cost but offer a longer life and better warranty conditions.

To meet your need for new or second-hand drug machines, you can purchase from reliable manufacturers or authorized suppliers and also get support from authorized services.