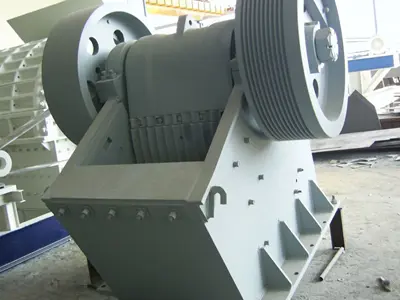

What is a Jaw Crusher?

It is one of the main crusher types in a mine or ore processing plant. It reduces large rocks or ores by compressing them. It uses compressive force to break the material. This mechanical pressure is achieved by the two jaws of the crusher, one of which is fixed and the other one is movable. These two vertical manganese jaws create a V-shaped gap called the crushing chamber, where the upper part is bigger than the bottom. The fixed jaw mounted at the 'V' alignment is the fixed crushing surface, while the movable jaw applies force to the rock by pushing against the fixed plate. The gap underneath the 'V' aligned jaw plates is the size gap of the crusher product or the broken product from the jaw crusher. The rock remains in the jaws until it is small enough to pass through the gap under the jaws. Jaw crushers are used in many applications to reduce the size of different types of materials. The jaw crusher is subject to two types of motion: one is a rotation movement towards the breaking side (which is called a fixed jaw due to the effect of a toggle plate) and the second one is a vertical movement due to the rotation of an eccentric. These combined movements compress and push the material through a predetermined size crushing chamber. The mechanical pressure is applied using the two jaws of the crusher; one corresponding while the other one is fixed. These crushers have primary and secondary types. Jaw crushers are one of the most preferred crushers due to their ability to crush materials of any hardness, low-cost operation, and easy maintenance.

The product works according to the principle of pressure crushing. The crushing material is crushed in the wedge-shaped pit between the fixed crushing jaw and the eccentric jaw attached to an eccentric shaft. The material is crushed and moved downward by an elliptical motion path. This continues until the material is smaller than the set crushing size. They are mostly used as primary crushers. Their main purpose is to reduce rocks to smaller sizes for the next crushing stages. Due to their ability to efficiently process large amounts of hard material, primary jaw crushers are a popular alternative. Because of their smaller physical size, jaw crushers are also ideal for tight spaces such as underground mining and mobile crushing applications. A jaw or toggle crusher consists of a series of vertical jaws where one jaw is fixed and the other jaw is moved back and forth by a cam or pitman mechanism. The jaws are farther apart at the top than at the bottom, forming a tapered chute so that the material is crushed progressively smaller and smaller as it moves downward. In this crusher, the moving jaw is pivoted at the top. The greatest motion is at the bottom, meaning there is less tendency to choke. The moving jaw in this crusher is pivoted at the bottom. Since the minimum movement is at the bottom, there is a greater tendency for choking. This product uses the engine as its power. The eccentric shaft along the motor wheels is driven by a V-belt and grooved wheel to move the movable jaw plate along a regulated track to ensure the movement.

Therefore, the materials in the crushing gap, consisting of the fixed jaw plate, the movable jaw plate, and the side lee panel, can be crushed and discharged through the discharge opening. You can access different machine groups through our portal. There are also many multi-functional product groups available. They help speed up production and minimize costs. You can find answers to many questions about products using the company contact information. The data and product content on our website are up-to-date information. This is the fastest and easiest page to access machine specifications and technical information. Our portal is developed with many product and company information. There are experienced, reliable, and quality company information in our sector on our portal. You can find many varieties of machine parts, equipment, attachments, spare parts, devices, tools, and industrial products using the search engine bar at the top of our website. Makina Türkiye website, which is the window opening to the global markets of Turkey, always lists the most up-to-date products quickly and enables buyers and sellers to meet at the most economical costs. Various features that meet customer demands are available at reasonable prices. Proven products and advanced technologies tailored to your application and budget are available on our page. It provides reliability, versatility, and precision. You can be sure that your industrial equipment needs are met with a wide range of products that can be selected and a constantly growing product range.

We are confident that with hundreds of quality suppliers and manufacturers, they can provide all equipment for your various industrial applications for sales, service, and solutions. The companies on our website always aim for advanced technology, quality products, and customer satisfaction, both domestically and internationally. You can quickly purchase a machine at a very reasonable price with quite affordable prices and easy payment options. The product varieties offered for sale by quality suppliers on our portal are manufactured. The products are manufactured using the latest technology techniques and components under quality assurance. You can easily place an order for products with zero and second-hand options that are designed to process a wide variety of materials with flexible production. Product varieties available for purchase through Makina Türkiye with easy payment options are offered at very affordable prices according to their qualities. Visit our portal for high-quality, low-cost products. Check our page for every budget-friendly product. You can even contact the machine sellers. Visit our page and procure the machine that fits your needs and budget. The desired machine is at an affordable price option here. Our products are offered with a guarantee.