Chocolate Resting Tank kategorisinde ürün bulunamadı.

Benzer kategorideki diğer ilanlar listelenmektedir.There is absolutely no rust in areas that come into contact with food in the chocolate machine. The capacity of the product varies depending on the material it will make. Each machine has its own unique function. Our machines are both sturdy and durable, and do not cause any harm to the food used. Our chocolate machines include chocolate tempering machine, chocolate melting machine, and chocolate coating machine.

At Makinaturkiye.com, our chocolate machines suitable for small, medium, and large businesses are available on our website. Our prices vary depending on the features and usage areas of the machines.

What is Chocolate Tempering?

Cocoa butter has various crystal structures. The main purpose of tempering chocolate is to ensure the crystallization of this cocoa butter at its core. The tempering process, which is an important process for preparing chocolate for work, aims to crystallize the cocoa butter inside the chocolate. This ensures a shiny and crispy product. The key point in tempering is to bring the chocolate to the right working temperature. The tempering process is a technique where the crystallization is controlled to obtain the most stable crystal form of cocoa butter before the chocolate turns from a liquid to a solid state.

Why Should Chocolate be Tempered?

Tempering chocolate is very important. It helps your chocolate harden while also giving it a shine. Tempering chocolate allows your chocolate to harden during cooling and makes it easier to come out of the molds used. If the chocolate you temper is poor or of low quality, it will start to turn gray as it is tempered and the desired shine cannot be achieved.

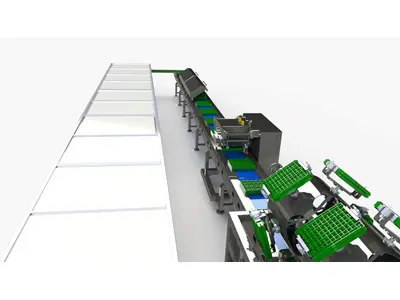

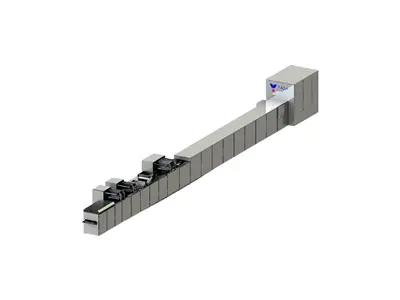

Our chocolate tempering machines have precise temperature control. They have high heat insulation. They also have a body resistant to corrosion and operate with low noise. The chocolate tempering machine has a dosing feature. It has a cooling system. The type of chocolate tempering machine varies according to its function and intended use. However, it takes up less space. It has features such as injection head, coating belt, and an expandable tunnel.

Which Chocolates Should be Tempered?

Every type and kind of chocolate is suitable for tempering. In fact, this depends on the place where the chocolate will be used. The tempering process ensures that you get the best quality chocolate. With the tempering process, you can use the tempered chocolate for any coating process. The chocolate tempering machine ensures the distribution of crystals inside the chocolate homogeneously. If you want your chocolate to have a shiny appearance, tempering is necessary, but if you only want to use chocolate as a flavoring ingredient, it can be used without tempering. So, not all chocolates need to be tempered; it varies depending on the intended use. The chocolate tempering machine also helps you melt the chocolate homogeneously before tempering.

What are the Steps to be Applied During the Chocolate Tempering Process?

There are 4 different steps to be applied in the chocolate tempering process. The first step is to completely melt the chocolate. Then, wait for it to cool down to the crystallization point. When it reaches the crystallization point, start melting the unstable crystals until they disappear.

Each chocolate entering the chocolate tempering machine goes through three different stages. Each stage is made of stainless steel. At the same time, the temperature of the water in each stage is automatically adjusted to keep the temperature constant. The chocolate capacity in the machine is adjusted with the help of a pump. The chocolate tempering machine has a mixer motor. There are temperature control systems for both chocolate and water. The incoming water from the operation is not mixed with the machine's own water, a suitable system is also working. The chocolate tempering machine does not wear out and is easy to clean with its disc. It has a body resistant to corrosion. Precise temperature control is carried out in the machine. There are various safety protections. Some of our machines have 4 safety protections. In addition, our chocolate tempering machines have high temperature insulation.

What is a Chocolate Coating Machine?

Many products can be coated with chocolate. Besides being beautiful in taste and appearance, it is important to extend the shelf life of the product by using a quality chocolate coating machine to coat the product with chocolate. The chocolate coating machine is designed to facilitate the chocolate confectionery or candy coating process in the food industry. With a simple operation, you can coat your products as desired, whether half or completely. The chocolate reservoir in the chocolate coating machine keeps the surface of the chocolate fresh by constantly refreshing it with a special mixer. With the chocolate coating machine, you can coat the part of your product with chocolate as you wish. You can coat only the bottom part of your product smoothly or only the top part. You also have the possibility to coat the product you will coat with various residues. By fixing the product you are coating, you can easily move the machine nozzle up and down, right to left. With the easily removable reservoir, you can coat your products with the chocolate you want. The chocolate coating machine is made of stainless steel products suitable for food. All the systems in the machine can be easily adjusted on the control panel. With this control panel, various settings such as chocolate temperature, lights, fan, cabinet temperature, coating thickness, belt speed, or coating method can be adjusted. The band width in the chocolate coating machine can vary according to customer demand. Some machines have a cleanable and replaceable air filter feature. The belt cleaning rollers prevent the belts from getting dirty. There is also an easy cleaning feature in chocolate coating machines.

Your chocolate coating machine is produced from stainless steel with makinaturkiye.com, the coating settings are made accurately, and it is suitable for coating many food products with chocolate.

What is a Chocolate Melting Machine?

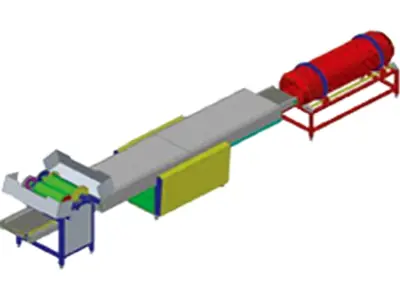

To melt your chocolate using the double boiler method, the chocolate melting machine not only melts the chocolate but also keeps the melted chocolate hot for a long time. The purpose of the chocolate melting machine is to ensure that the molded chocolates are used in a melted form. It is a product that will be actively used in the chocolate melting process. It has a hygienic and easy-to-clean feature. Precise temperature adjustment can be made with the adjustable thermostat system. It has both digital and mechanical temperature control. The chocolate melting machine is suitable for commercial use. It is a professional product. The chocolate melting pot quickly melts the chocolate and occupies little space. The chocolate double boiler melting machine can be used to melt chocolate as well as for hand chocolate tempering process. The machine has a stainless steel basin. The body part is made of an insulating material to ensure the homogeneous melting of chocolate. No harmful substances are used in the areas in contact with food. You can melt your chocolate at the desired temperature with the adjustable thermostat. There are various bucket options for the chocolate double boiler melting machine. The chocolate melting machine ensures equal heat at both the bottom and side bodies in the industrial field, allowing the chocolate placed in the machine to melt homogeneously. The liter volume of the container may vary in each machine. The chocolate double boiler melting machine also has an easy-to-clean feature.

To perform the double boiler melting process for your chocolate, you can find the chocolate melting machines suitable for your home, business, or institution on our website makinaturkiye.com.