Food Production Facility

Food production facilities are industrial areas specially designed for processing, packaging, and distributing food products. The installation, management, and operation of these facilities should be carried out in accordance with specific standards and regulations.

An industrial area where various food products are produced, processed, and packaged, a food production facility is usually designed and operated in compliance with hygiene and safety standards. A food production facility offers suitable solutions for both large-scale production factories and smaller, specialized production businesses.

How to Establish a Food Production Facility?

The first step in establishing a food production facility is selecting a suitable location and designing the facility. After the location is chosen, the planning of the facility, procurement of necessary equipment, and installation processes are carried out. During installation stages, compliance with local and international food safety standards must be ensured. In this process, obtaining consultancy services for a food production facility can help ensure that the installation is done more efficiently and in accordance with standards. The stages of establishing a food production facility include location selection, design, construction, equipment procurement and installation, trial production, and reaching full operational capacity.

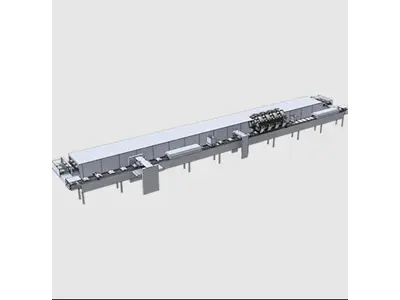

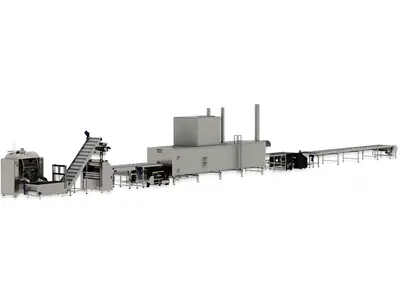

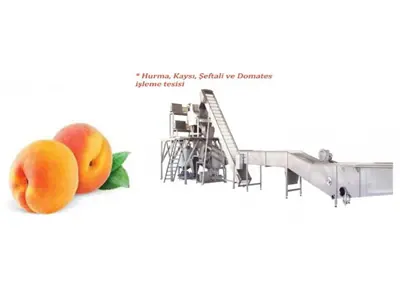

What Equipment Is Required for a Food Production Facility?

The equipment used in food production facilities varies depending on the type of food to be produced. However, generally, processing machines, packaging machines, storage equipment, and equipment to ensure hygiene conditions are necessary. For example, a dairy production facility requires pasteurization machines, filling machines, and cooling units. Equipment in a food production facility enables the production process to be carried out efficiently and safely.

How Is Food Production Facility Management Done?

Food production facility management ensures that production processes are carried out efficiently and safely. This includes personnel management, production planning, quality control, and the implementation of hygiene standards. Food production facility management ensures that the facility consistently produces high-quality products and complies with food safety standards.

What Should Be Considered in Food Production Facility Design?

Hygiene, safety, and efficiency should be paramount in facility design. Additionally, optimizing workflow and providing an ergonomic environment where personnel can work comfortably should be ensured. The design of a food production facility should be done in a way that ensures each stage of production runs smoothly.

What Are the Hygiene Standards in Food Production Facilities?

Hygiene standards in food production facilities are critically important to ensure food safety. These standards include cleanliness protocols, sanitation procedures, and personnel hygiene rules. Food production facility standards should comply with national and international regulations. Standards like HACCP, ISO 22000, and GMP encompass procedures aimed at ensuring hygiene and safety throughout the facility.

What Are the Costs of Establishing a Food Production Facility?

The costs of establishing a food production facility vary depending on the size of the facility, the equipment used, and the required regulations. Generally, construction costs, equipment costs, and operating costs of the facility should be taken into account. The costs of a food production facility can vary significantly depending on the scale and goals of the business. A food production facility can have an average price range of {price_range}.

To meet your needs for a new or used food production facility, you can purchase from reliable manufacturers or authorized suppliers through makinaturkiye.com and also get support from authorized services.