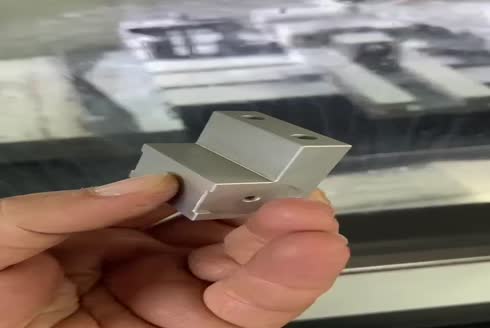

Fason Silindir Boru Bükme İşleri

Rolling Bending Works

It holds an important place in metalworking. This service is used particularly in various sectors to bend metal parts to the desired diameter and direction. This method used in creating cylindrical shapes enables you to achieve sturdy and aesthetic results. With our outsourcing rolling bending service, you can perform high-quality, durable, and flawless bending operations in your projects.

Outsourcing rolling bending is the process of bending metal sheets or profiles to a specific diameter. This process is preferred especially when traditional bending methods such as forging, pressing, or other methods are difficult to use. Rolling bending process is generally applied on materials like steel, aluminum, and stainless steel and has a wide range of applications in the industrial field. Outsourcing this service allows you to obtain high-quality results from expert teams external to your organization.

Advantages of Outsourcing Rolling Bending

-

High Precision: Rolling bending ensures the correct bending of the material at precise angles and desired diameters. This is a major advantage, especially in projects where design and functionality are critical.

-

Various Material Options: Bending process, applicable to different materials, can be used in various metals such as steel, aluminum, stainless steel, and others.

-

Durable and Long-Lasting Results: Bending cylindrical shapes in a durable manner provides high performance and long life, especially in industrial use.

-

Flexibility: Bending can be done on metal parts of different diameters and lengths. This flexibility offers adaptable solutions for all your projects.

Where is Outsourcing Rolling Bending Used?

Outsourcing rolling bending has a wide range of applications in many industrial sectors. Here are some sectors where this service is widely used:

-

Construction and Building Sector: Aluminum or steel cylindrical structures are commonly used in the construction sector. Rolling bending is necessary, especially for structures such as roof systems, metal beams, and pipes.

-

Automotive and Transportation: In the automotive sector, bending of cylindrical metal parts is frequently done, especially for vehicle chassis and transport machinery.

-

Manufacturing of Machinery and Equipment: In the production of cylindrical parts required for industrial machines, precise bending is of great importance. This ensures the proper functioning of machine parts.

-

Pipelines and Pipelines: Cylindrical shapes are also widely used for pipeline systems. With the rolling bending process, parts in correct sizes and suitable structures are produced for such systems.

-

Art and Design: Aesthetic rolling bending processes are also carried out for metalworking and art pieces.

Why Should You Choose Us?

-

Experienced Team: With our expert team, we perform your rolling bending operations with high precision and complete each project meticulously.

-

On-Time Delivery: By delivering your projects on time, we prevent disruptions in your workflow. With our efficient work principles, we deliver your projects quickly and securely.

-

Reasonable Prices: By offering our quality and professional rolling bending service at reasonable prices, we help you keep your costs under control.

-

Quality Control: We prioritize quality at every stage, ensuring the necessary controls to carry out the bending process to the highest standards.