Fason Metal Parça Konik Mil Ve Yuva İmalatı 2

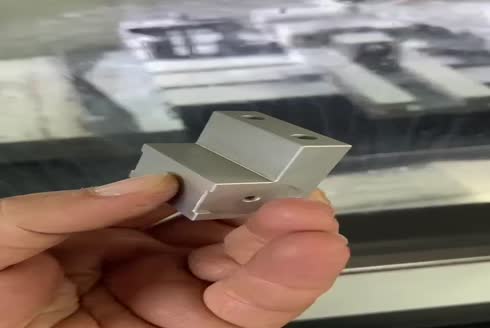

Custom Metal Part Tapered Shaft and Slot Production

Budak Makina is one of the most reliable solution providers in the sector for custom metal part tapered shaft and slot production. Tapered shafts and slots are of critical importance especially in machine manufacturing, automotive, automation, and other industrial applications.

These parts are specially produced for applications requiring high precision and durability. At Budak Makina, we offer high-quality, flexible, and quick solutions to meet all your tapered shaft and slot needs.

Advantages of Tapered Shaft and Slot Production

-

High Precision: The accurate production of tapered shafts and slots ensures the proper operation of the system and high efficiency. Shafts and slots are manufactured with precision using CNC machines and modern processing technologies.

-

Durability and Longevity: Thanks to the quality materials and processing techniques used, tapered shafts and slots offer long-term durability. They have high resistance to wear and tear.

-

Customized Designs: Tapered shaft and slot parts can be customized according to our customers' needs. Dimensions, material types, processing methods, and other features can be tailored based on specific requirements.

-

Efficient Production Processes: By offering economical solutions for high-volume production, we ensure that your projects are completed on time and within your budget.

Custom Tapered Shaft and Slot Production Process

-

Design Phase: The design of tapered shaft and slot parts is carried out according to our customers' requirements. Functionality, material selections, dimensions, and other technical requirements are taken into account at this stage.

-

Production Process: Tapered shafts and slots are produced using CNC machining, turning, milling, and other modern production techniques. Each part is processed with maximum precision and manufactured in accordance with high-quality standards.

-

Quality Control: The produced tapered shafts and slots undergo quality control tests. Criteria such as dimension measurements, fit tests, durability, and functionality are checked to ensure that the parts are flawless.

-

Final Processes and Delivery: The produced parts are packaged after final processing and coating (if necessary) and sent to the customer for delivery.

Applications of Tapered Shaft and Slot

-

Automotive Industry: Transmission systems, differential gears, drive shafts, and other transport mechanisms.

-

Machine Manufacturing: Industrial machines, pump systems, motor parts, and other mechanical systems.

-

Heavy Manufacturing and Construction Equipment: Tapered shafts and slots with high durability for cranes, construction machinery, and processing machines.

-

Automation Systems: Precision tapered shafts used for robotic arms, drive systems, and conveyor lines.

-

Marine and Maritime: Shaft and slot systems with high durability in ship machinery and maritime equipment.

Why Budak Makina?

-

High-Quality Production: Each part is produced with high-quality materials that comply with industrial standards. We provide durable, long-life tapered shafts and slots.

-

Modern Production Technology: We ensure high-precision production using CNC machines and other advanced processing equipment.

-

Flexibility and Customization: We offer design and production options according to every customer's request. Dimensions, material type, and processing techniques can be customized.

-

On-Time Delivery: With our highly efficient production processes, we deliver your projects on time.

-

Competitive Prices: We provide cost efficiency by offering high-quality production at competitive prices.