4-Unit Edge Banding Machine kategorisinde ürün bulunamadı.

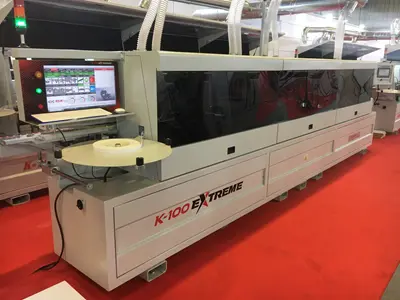

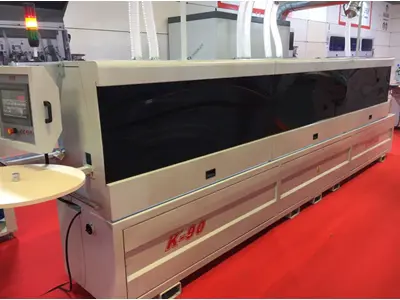

Benzer kategorideki diğer ilanlar listelenmektedir.Edge Banding Machines for Serial Production

Edge banding machine is used in carpentry to create durable and aesthetically pleasing edges. Various types of edge banding machines such as edge trimming for start and end cutting, window sills machine, curved, milling, fully automatic, scraping edge banding machines are used for edge covering processes aiming for an aesthetic appearance similar to the surface on the edges. Loading-unloading lift, corner rounding, laser, guillotine, plain, 2-unit, 3-unit, 4-unit, 5-unit, 6-unit edge banding machines, sizing edge bonding machines are used. High-quality and cost-effective edge banding machines are available on our page. While edge banding machine is not a particularly difficult skill for mastery, it is a machine that makes the job much easier and faster, handling most of the work on its own. This machine feeds the material, attaches the edge banding to the surface, and trims the edges. This machine is critical for the quality look of your furniture. It tends to apply adhesive to the edges of cabinet tops, tables, and plywood panels.

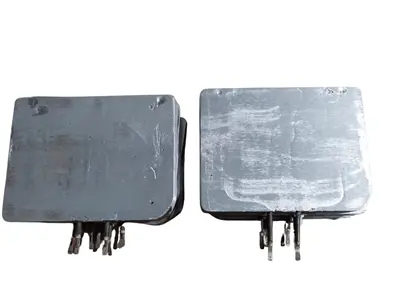

Traditional edge banding was a manual process that required ordinary carpentry tools and materials. In modern applications, especially for high-volume, repetitive production stages such as cabinet doors, edge banding is applied to the substrate using an automatic process with a hot melt adhesive. Hot melt adhesives can be water-based or solvent-based and can consist of various raw materials including EVA, PUR, PA, APOA, and PO. A substrate primer can also be used as a binding agent between the adhesive and the substrate. Thicker edge bands typically require a slight vibration to provide a tight glue line. The thickness can vary between 0.018" and 5 mm or more. The machine that applies the edge band is called the edge banding machine. Edge banding machine applies the edge band to the substrate, trims the top and bottom edges, trims the top and bottom layer at the same level with the substrate, removes the waste, and polishes the finished edge. Applying the edge band in a spread shape creates a collection of natural problems not found in flat panels or rails. Any deformity or irregularity on the edge surface or top/bottom edge easily makes contact with the edge band material and affects the adhesive bond strength.

The smallest edge banders have several features related to simply attaching trim material to the workpiece. Among the smallest machines, there are quite refined features including strong feeding and workpiece guidance mechanisms. In such machines, compression pressure is manually applied as the workpiece passes through the feed rollers. The use of pre-glued veneer strips is more popular among small machines, but some have adhesive application systems for limited production. Feeding edge banding tapes can have individual task capabilities and be single or double-sided. An apparatus for supplying and feeding a roll or strip of edge banding material, a system to control and apply the required adhesive, a refined system to hold and compress the workpiece during the adhesive curing time, both pre and final edge trimming, top and bottom edge trimming, top and bottom edge bevel breaking or smoothing, and features such as sanding, polishing, or scraping of finished edges are shown. Small feeding machines are limited to straight edge banding processes. Most cannot perform corner rounding or shaped edge banding. There are several small manual or highly automated edge banding machines for special products like S-shaped edge band.

PVC Edge Banding Machines

Most machines available in the market today can apply edge banding to panels or rails with a thickness of more than 8 mm up to 60 mm or more. The length and width of workpieces and edge banding materials that each machine can apply can vary based on the specific market segment chosen by each machine manufacturer. Many units become more versatile as they go. Edge banding is used to cover the exposed surfaces of materials such as plywood, chipboard, or MDF to increase durability and provide the look of a solid or more valuable material. Common applications of edge banding include edgebanding face frames or molding. Edge banding can be made from different materials including PVC, ABS, acrylic, melamine, wood, or wood veneer. Edge banding machines that will best meet your needs can be found on our page. Hundreds of brands and models are available in the Edge Banding Machine category with options for sale or rent and the ability to contact the seller instantly.