Aerosol Filling Machine Varieties

Aerosol filling machine, also known as spray filling machine, disperses a substance or a leak in a gas environment. We can define them as systems that perform liquid filling, valve placement, and then gas filling processes. The aerosol filling machine, designed to dispense the liquid inside as a mist or foam, is generally in the form of a metal can or plastic bottle. Hair sprays or shaving foams can be given as an example of this. When you shake it, a bottle-like air or foam comes out of the bottle that you feel there is liquid inside. Aerosol cans, initially developed to spray insecticides, are now used for a wide range of products. The propellant gas is a mixture of compressed liquefied gas or gases. Therefore, the propellant gas mixture evaporates rapidly as soon as it comes into contact with the atmosphere while the active substance remains on the hair or skin. The aerosol filling machine designed to fill aerosol cans provides indispensable assistance for companies operating in various sectors of the chemical, pharmaceutical, and cosmetic industries.

The principle of operation is the same for foam and powder aerosols. Attention is paid to the propellant gases used as being odorless and colorless, non-toxic, and non-flammable. Improper use of this product can lead to accidents. If you are a hair spray manufacturer, produce spray insecticides for pest control, or are a completely different hair or shaving foam manufacturer, all you need is a spray filling machine. Finding an aerosol filling machine that fits your budget is very easy. With two different models, automatic and semi-automatic aerosol filling machines, you can make your choice depending on the size of your business, budget, or number of employees. This aerosol filling machine, which can cater to hundreds of different sectors, has a complex working structure. There is a different aerosol filling machine for each sector. There are different aerosol filling machines for different hair care products for pest control. Our aerosol filling machine, regardless of the properties of tinplate cans, can be used to fill tinplate cans with various liquid products. This means that the aerosol filling machine can be used for foamy, caustic, dense substances, as well as unspecified other liquids. When necessary, the semi-automatic aerosol filling machine can be reinforced with a suitable filling head. You can buy an aerosol filling machine right away with very affordable prices and easy payment options. The aerosol filling machine varieties offered for sale by quality suppliers on our platform are manufactured.

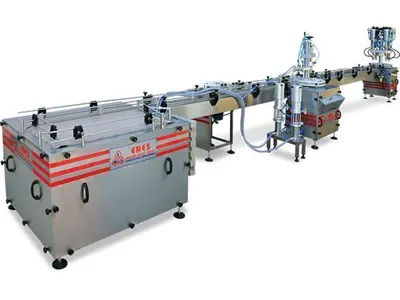

In a fully automatic aerosol filling machine, empty cans are lined up on the unit to be filled. After filling in the liquid filling unit with the help of a conveyor, a process called valve closure is performed. The cans, which have been filled with liquid and valve closed, optionally pass through the inkjet unit and finally reach the gas filling unit as the last step. The use of a fully automatic aerosol filling machine is very easy. There are liquid filling unit, valve closure unit, and gas filling unit in the parts called can feeding unit. Our companies produce aerosol filling machines in various variations upon request. Aerosol filling machine with various models are waiting for you on our page. Visit our page now to identify the most suitable aerosol filling machine for your needs, get in touch with the seller, and get information. Aerosol filling machine options, detailed advertisements, and price options are here. Hundreds of brands and models, the possibility to instantly reach the seller, buying and renting options are available in the filling machines category under Aerosol Filling Machine headline.