Compact Concrete Plant kategorisinde ürün bulunamadı.

Benzer kategorideki diğer ilanlar listelenmektedir.Concrete Batching Plant in Ready Mixed Concrete Production

For construction and building operations, you can find the most suitable concrete batching plant models on the page according to your needs and provide solutions. Concrete batching plants, which are used in Ready Mixed Concrete Production and are very important equipment, are offered to you at the most affordable prices and high quality standards, allowing you to choose the right model for your work.

What is a Concrete Batching Plant and Why is it Used?

For sale concrete batching plant is especially important for businesses in the construction and building sector because it offers great convenience. Basically, a concrete batching plant is a facility that allows stocking of ready-mixed concrete components such as cement, water, sand, gravel, and aggregate, mixing them in specified quantities to produce ready mixed concrete, and also allows filling when needed. As can be expected, these facilities have a very important place in the construction and building sector. Concrete batching plants consist of various mechanical, pneumatic, hydraulic, and electronic parts that provide the mixing, control of the required amounts, and transportation of the basic materials that make up the concrete. Components that contribute to the formation of the concrete batching plant include aggregate bunker, weighing belt, mixer feeding belt, cement silos, cement helix, mixer, and automation, and therefore, a concrete batching plant has a compact structure consisting of different parts. These parts are carefully assembled to form the concrete batching plant. With the concrete batching plant models offered on the page, you can choose the models that meet your needs.

What are the Types and Prices of Concrete Batching Plants?

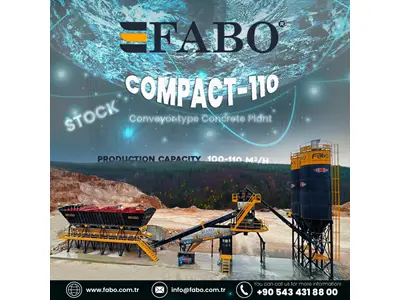

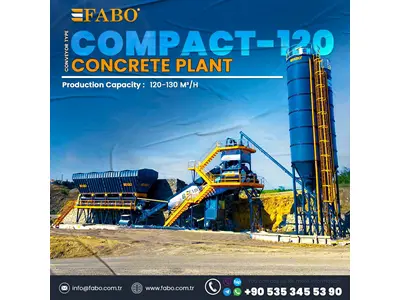

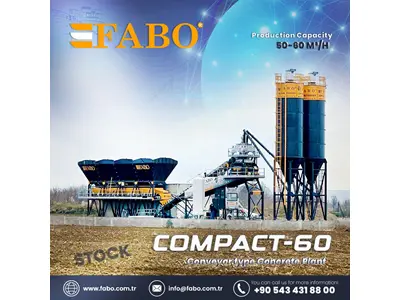

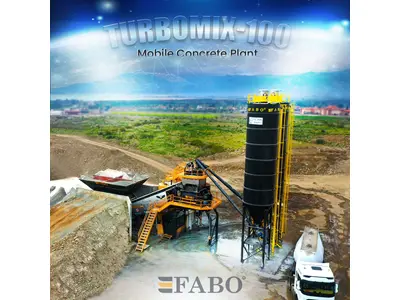

Concrete batching plant models differ to meet the needs and facilitate construction operations. In this respect, each plant has its own unique features. Fixed concrete batching plants, which are preferred for large projects and long-term jobs, are set up in a single area and ensure concrete acquisition from the location where they are installed. On the other hand, if it needs to be moved to a different area after a short time or at the end of the project, mobile concrete batching plant is often preferred. For projects where transportation costs are important, compact concrete batching plant is preferred, and for projects where investment costs need to be low, Scraper concrete batching plant can be preferred.

All these plant models are determined according to the needs, and by comparing the prices of concrete batching plants offered on the page, you can easily choose the model that will meet your needs.

What to Consider When Choosing a Concrete Batching Plant?

Certain points should be considered when choosing a ready mixed concrete batching plant. When choosing concrete batching plants with different brands and models such as Göker concrete batching plant offered on the page, the selection should be made primarily to meet the needs in the most suitable way. If a fixed concrete batching plant is preferred, it should be considered that this plant will not move later, and dismantling operations will create a significant loss of time in places where it needs to move. However, although fixed concrete batching plants remain fixed, they offer more affordable prices and longer-term uses. If the plant movement is not required afterwards in the project and if the project will last for a long time, in this case, choosing a fixed concrete batching plant will be a better decision. Such concrete batching plants consist of systems that produce concrete and also provide mixing of materials. Equipment that makes up a fixed concrete batching plant generally consists of cement silos, aggregate bucket, concrete mixer, bunker, scale, and other parts.

Basically, mobile concrete batching plant also has the same parts; however, they can be used in different projects as they can move due to their structures. If you are conducting short-term projects or want to provide concrete for projects in different areas, choosing a mobile plant would be better.

Advantages of Concrete Batching Plants in Concrete Production

If a concrete batching plant is chosen to be mobile, it is useful to know the advantages it offers. While fixed concrete batching plants were used more in the past, mobile batching plants, which can easily move today, are available. Mobile plants offer a great advantage for companies to easily use them in other projects after completing their projects. As dismantling and installation operations are laborious in fixed plants, mobile concrete batching plant models are often chosen to meet the needs of short-term projects or to respond to different projects at the same time. Mobile models, which stand out with their flexibility, ease of transport, and quick installation, are designed to easily fit onto a mobile frame with axles and wheels behind all their parts. Thus, they can be easily transported to any desired location via a truck.

Mobile concrete batching plant advantages are numerous. First and foremost, easy transport offers great convenience. The main unit of the plant can be pulled with just one truck. Offering quick and easy installation also helps to get better results for very short-term projects. It being easily movable also creates extra flexibility for users. Since it requires less space for installation compared to fixed models, it can be installed inside the project area, thus providing significant savings in terms of time and economy. Since it requires less foundation for installation, it can be easily installed on a flat surface. Due to its practical and fast installation, there is no need to obtain necessary permissions for the installation of a mobile concrete batching plant in some cases. Mobile concrete batching plant models, which offer great benefits in terms of these aspects to construction companies working on project basis, can be easily found on the page and you can choose the model that will best meet your needs according to their capacities.

High Efficiency in Concrete Batching Plant in Areas You Need

Tekno Design concrete batching plant or other plant models always enable you to produce at the capacity you need. Regardless of which plant model you choose, models that make concrete production fast, safe, and practical help projects progress much more efficiently. With all these features, concrete batching plant models help your projects to be completed in the best way. Concrete batching plant models like this are also offered to you on the page to easily select the right plant for your project.

Most Affordable Concrete Batching Plant Models

You can obtain the most affordable concrete batching plant models according to the manufacturer brands and the costs in the city where they are produced on the page. By comparing different models and manufacturers based on their structures and volumes, you can easily choose the right model. Regardless of the model you choose based on your project and workload, it will always offer you great convenience in concrete production with high capacity. After the installation of the most affordable concrete batching plant, it will allow your projects to progress faster and complete your projects on time. Models made of high-quality materials and advanced equipment on MachineryTurkey.com provide great convenience to companies producing ready-mixed concrete.