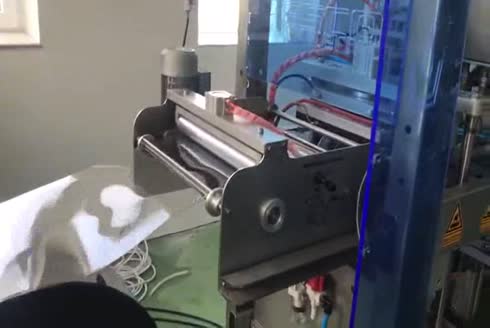

760 mm Thermoform Packaging Machine 2

A-Zform SY7340S

760 mm Thermoforming Packaging Machine

- Mold Closing Force: 32,500 (daN)

- Max. Film Thickness: 2.2 mm

- Min. Film Thickness: 0.30 mm

- Max. Film Width: 760 mm

- Speed: Empty cycle: 0-40 cycles/min

- Formed Product Depth: 160 mm

- Air System: 4-point triggered valve entry – special large tanks

- Pitch: 480 mm

- Air Requirement: 8 Bar 8 m² (System with entrance filter)

- Water Pressure & Temperature: 3.4 bar, 10°C 50,000 Cal (Automatic control system with entrance filter)

- Water Inlet & Outlet: Lower mold, upper mold, pusher, and chain arms, 4 inlets, 4 outlets

- Suitable Materials for Forming: PET, PP, PS, PVS, ABS, PLA

- Electrical Power Installed: 120 kW (max load)

- Communication: Ethercat Motion Control

- Automatic Chain Lubrication: Bekamaks

- Weight: 18,500 kg

- Pneumatic Equipment: SMC, Mac

- Automatic Machine Grease Lubrication: Bekamaks

- Mold Cutting Adjustment System: Motorized, special production gear transmission shaft system

- Remote Control: Remote control and monitoring via internet connection

- Seal System: 4-point centered bearing, special mechanical design, 50x50 THK threaded shaft

- Electrical & Electronic Equipment: Omron

- Max. Film Width: 760 mm

- Program Memory Upload: Recipe registration, automatic transfer via USB

- Colors: RAL 9010, 9017, 3002, and 7011

- Vacuum Pump: 2.2 kW Schmalz

- Coil Feeding: Hydraulic system with max 1800 kg capacity

- Safety: Closed cabin, rail cover switch system

- Resistor: Ferran reflector, Elstein FSR (Germany) 650-1000 V

- Reducers: Motive-Watt Drive, Sew-Eurodrive-Aden

- Number of Resistors: Total 330, Upper: 12x8 & 15x6, Bottom: 12x12

- Film Entry Chain Resistor: 2 x 2 pieces

- Operator Panel: 15” Omron or PC panel 15”

- Chain Arms: Full-length aluminum water-cooled, 2379 58-60 HRC steel, special protective system, heat protection, Ferran reflector

- Mold Change: Special tool for upper and lower molds, chain hoist

- Automatic Tensioning System: Spring-loaded

- Moving Cable & Hose Transfer Channel: CKS Moving Cable

- Seal Servo Motor: 7.5 kW Omron with brake

- Chain Servo Motor: 5 kW Omron without brake

- Main Servo Motor: 7.5 kW Omron with brake

- Camera System: 4 MP Hikvision brand camera system, records for 30 days from 4 points

- Pneumatic Equipment: SMC

- Carrier Servo Motor: 5 kW Omron without brake

- Elevator Servo Motor: 1.5 kW Omron with brake

- Talon Servo Vertical Motor: 2 kW Omron with brake

- Talon Servo Horizontal Motor: 2 kW Omron with brake

- Front Loader Defect Asynchronous Motor: 1.1 kW with brake (Motive)

- Exit Defect Winder Asynchronous Motor: 1.5 kW (Motive)

- Vacuum Pump: 2.2 kW Schmalz

- Conveyor Asynchronous Motor: 0.18 kW

- Stacker: 0.25 kW, Linear Cramayer Motor

- Electric & Electronic Equipment: Omron, Sick

- Min. Stacking Quantity: 25 pieces

- Max. Stacking Quantity: 100 pieces

- Min. Product Depth: 25 mm

- Max. Product Depth: 180 mm

- Stacker Change: Manual push-pull system with a sled

- Waste Winding: Pneumatic piston unloading

- Inline Waste Breaker: Machine and cabinet direction reversing system

- Safety: Cabin with rail cover switch system

- Rotation Axis Mechanism: 180°

- Product Transfer to Conveyor: Linear central system with sweeper piston

- Elevator Collector: Up & down with belt, linear shelf system

- Product Packaging Transfer: Conveyor belt

- Product Removal from Mold: Vacuum precision holding mandrel system

- Communication: Ethercat Motion Control

- Program Memory: Recipe registration, automatic loading via USB

- Product Transfer from Stacker: Vertical & horizontal linear piston system

- Mold to Stacker Brush Transfer: Pulley system with linear car

- Moving Cable & Hose Transfer: CKS moving cable channel

- Automatic Grease Lubrication: Bekamaks

- Defective Product Separation: Separate outlet with special conveyor trough

Sıradaki