13,500 Pieces / Hour PTW-10 Cup Water Filling Machine 1

İngilizce:

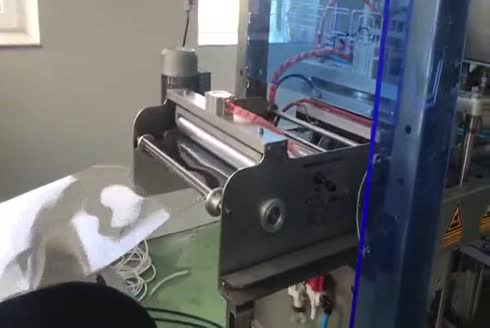

13,500 pcs/hour PT-W 10 Cup Water Filling Machine

- 100 cm diameter lower coil feeding unit

- 4-stage heating unit

- Air pressure control and circuit breaker system

- Fully protected stations with covers

- Flexi glass doors

- Pneumatic piston-operated MAÇA unit

- Servo motor-operated forming station

- Level-controlled feeding valve

- Water filling tank

- PLC time-controlled water filling valves

- Upper foil holder and heated tensioning system with pneumatic shaft

- Photocell heated tensioning system

- Servo-operated gluing station

- Upper pressure piston-reinforced gluing unit

- Servo-operated & screw pull unit

- Reducer-driven crank arm cutting unit

- Lubrication system on column shaft and bearings

- Upper foil waste winding unit

- Lower foil waste cutting and winding system

- Cabin interior lighting

- Adjustable conveyor height at the cutting exit according to the cup CC size

- Pneumatic valves and pistons FESTO - SMC - MIDMAN - PNÖMAX (Japanese)

- PLC system is OMRON (Japanese)

- Control screen with 10” COLOR TOUCHSCREEN

- Servo and drive equipment (OMRON)

- All contactors and motor protections will be Siemens, Telemecanique, or Schneider

- Stainless steel air balance tank is standard on the machine

- The machine uses 7075 Aluminum and 304 & 316 L quality stainless steel

- Observation glass is available on the water filling tank

- The water filling tank is cylindrical to ensure complete hygiene (316 L)

- CIP washing nozzle and inlet connection are available in the filling tank

- The machine frame structure is made of stainless profile sheets

- Visual alarms for all fault conditions

Sıradaki