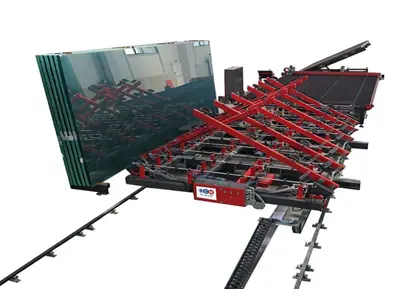

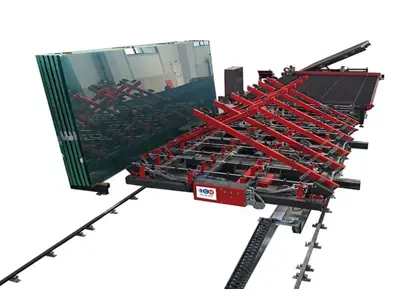

Glass Cutting Machine

A glass cutting machine is an industrial device used to cut and shape glass materials. These machines are designed to precisely cut glass sheets, glass plates, glass cutting board, or glass panels using special diamond or carbide blades. They provide high precision and repeatability while performing operations such as measuring, cutting, and straightening the edges of glass. Glass cutting machines are widely used in construction, automotive, furniture, showcase design, and many other industries.

Glass is used as an important material for many industries and domestic applications. Precisely cutting glass is a critical step in many projects. Therefore, glass cutting machines play an important role in the glass industry and the construction sector. These are specially designed machines to ensure the precise cutting of glass. They often work on a glass cutting board or table placed on the glass. The basic working principle is to cut the glass slab to the desired size or shape using a cutting wheel or laser light.

Types of Glass Cutting Machines

Glass cutting machines are specialized machines designed to cut, shape, and process glass sheets. These machines come in different types: Glass cutting tables are used for basic manual cutting, while CNC glass cutting machines are preferred for computer-controlled precision cutting and processing operations. Additionally, optical glass cutting is used especially in the precise cutting of eyeglass lenses and optics. This variety includes a range of glass cutting machines using unbreakable glass cutting board to meet different requirements in the glass industry, construction sector, and many other applications.

- Optical Glass Cutting Machines: These are special devices designed for the precise cutting and shaping of glass materials used in the optical sector, such as optical components like glass lenses or eyeglass lenses. These machines ensure the high-precision cutting of glass and processing according to specific optical requirements. They often have computer-controlled systems and automate the cutting process, minimizing the risk of errors and enhancing product quality. They are widely used in fields such as eyewear production, optical lens production, telescope and microscope manufacturing, ensuring the accurate cutting of optical components.

- CNC Glass Cutting Machines: These machines are specially designed to cut glass materials with high precision using Computer Numerical Control (CNC) technology. They follow cutting patterns and dimensions pre-loaded into computer programs, enabling them to perform complex or customized cutting operations. The CNC glass cutting machine is used in furniture production, showcase design, glass industry, and many other applications. These machines increase productivity by performing cutting operations with high precision and ensuring repeatability.

- Laser Glass Cutting Machines: These are special devices designed to cut glass materials with high precision using high-energy laser beams. These machines concentrate laser beams to melt or vaporize specific regions of the glass, thus performing the cutting process. Laser glass cutting can provide access to the complex and fine details of glass and perform the cutting process with high precision. These machines are widely used in glass art, glass decoration, glass processing industry, and the production of special glass products. Laser technology ensures fast and precise cutting processes and facilitates the engraving of special designs or complex patterns on glass.

- Tempered Glass Cutting Machines: These machines are specially designed to cut special types of glass with the unique durability of tempered or toughened glass. These machines process tempered glass without compromising its unique properties by ensuring precise cutting and shaping of the glass. They are widely used in industries such as construction, automotive, and furniture where tempered glass is used. These machines allow the cutting of tempered glass into accurate dimensions and shapes, supporting the production of durable and safe glass products.

Areas of Glass Cutting Machine Applications

Glass cutting machines have a wide range of applications from the construction sector to the automotive industry, furniture production to glass art. These machines are essential tools for many industries and applications that require precise cutting, shaping, and processing of glass sheets. In the construction sector, glass cutting machines are used in the production of construction materials such as window panes and door glasses, while in the automotive industry, they are crucial for cutting and shaping car glasses. Additionally, they are used in creative applications such as cutting glass coatings in the furniture industry and creating decorative glass panels in glass art. Sectors where glass cutting machines are common:

- Construction: Glass cutting machines are used to cut construction materials such as window panes, door glasses, facade glasses, and structural glasses.

- Automotive: Glass cutting machines in the automotive industry are used in the production of car glasses, glass roofs, and vehicle windows.

- Furniture: Glass cutting machines for furniture production are used to cut and shape furniture parts such as table tops, shelves, and showcase glasses.

- Glass Industry: In the glass manufacturing and processing industry, they are used for cutting and shaping glass sheets, glass plates, and special glass products.

- Glass Art: Glass artists can use glass cutting machines to create stained glass works, glass sculptures, and other artistic glass pieces.

- Glass Decoration: Glass cutting machines are used for the production of glass decoration products, such as cutting mirrors and glass panels.

- Electronics: Glass cutting machines are used in the production of screen glasses and other glass components for electronic devices.

- Medical: Glass cutting machines can be used for the production of glass components for medical devices.

These sectors are just a few of the common areas where glass cutting machines are used, and these machines are essential for many industrial and commercial applications that require the cutting and shaping of glass materials.

Glass Cutting Machine Prices

Glass cutting machine prices vary depending on the machine type, brand, functionality, and cutting capacity. A basic desktop glass cutting machine can start from thousands of dollars, while industrial CNC or laser machines can have higher costs. Optical glass cutting machine prices and tempered glass cutting machine prices are generally more expensive. Local market conditions can also influence prices. Glass cutting machines play an important role in the glass processing sector and are used in various application areas. Machine selection and pricing will vary depending on your needs and budget. It is important to conduct careful research when choosing the most suitable glass cutting machine for your business. Tempered glass cutting in Izmir and Istanbul is provided by many glass cutting workshops and companies located in major cities. These workshops and companies can tailor tempered glass to specific sizes and shapes, meeting customers' needs. The special durability of tempered glass leads to its widespread use in construction, automotive, furniture, and many other industries. If you want to receive tempered glass cutting services from tempered glass cutting Istanbul or Izmir, you can contact glass cutting companies in Izmir or Istanbul and communicate your requests for tempered glass cutting tailored to your needs. These companies can generally meet special cutting requests and prepare tempered glass for specific projects.