EPS / Styrofoam and Siding Machines

EPS and styrofoam machines are special machines used to expand, shape, and cut polystyrene materials. Among these are various equipment such as block molding machines, cutting machines, mold machines, and recycling machines. EPS / Styrofoam and siding machines are indispensable in the construction and packaging sectors. These machines offer quality products with the precise production and shaping of materials. By using the right machines, manufacturers can provide high-quality products and increase efficiency to gain a competitive advantage in the market.

EPS / Styrofoam:

EPS stands for Expanded Polystyrene and is commonly known as styrofoam. This material, usually white, is a lightweight polymer with good insulation properties. It is widely used in the construction sector for heat and sound insulation and in various packaging applications. EPS machines are used to produce this material in blocks or panels and then special machines are used to cut them into the desired sizes and shapes.

Siding:

Siding is a building material commonly used as a decorative element on the exterior facades of buildings. Mostly made of EPS, polyurethane, or other composite materials, it is used to give an aesthetic look to window and door surrounds or building facades. Siding machines are used to produce these decorative elements with precision and can create siding profiles in different sizes, shapes, and details.

How do Styrofoam and Siding Machines Work?

Styrofoam Machines:

EPS (Expanded Polystyrene) or styrofoam machines produce lightweight, durable, and insulating EPS products. The basic operation stages of these machines are as follows:

Pre-expansion: Polystyrene granules are heated with steam in expansion units to transform them into EPS particles. During this process, the granules expand their volumes several times.

Aging: Expanded EPS particles are allowed to rest for a while to let the steam escape from their cellular structures.

Molding: Aged EPS particles are placed in molds and heated with steam to stick together and take the desired shape. Block molding or shaping machines are used at this stage.

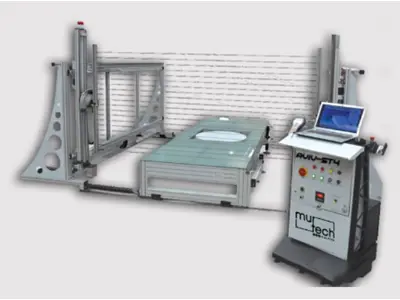

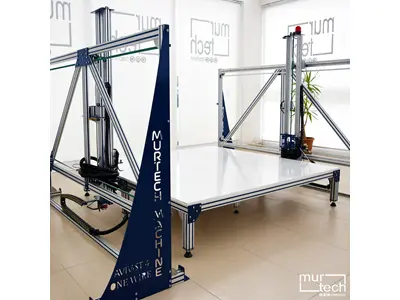

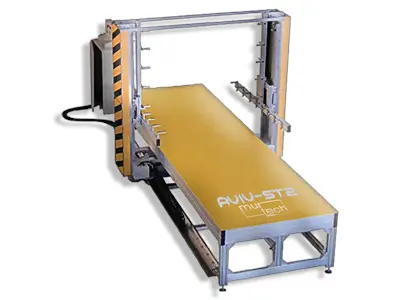

Cutting: The produced blocks are cut into the desired sizes and shapes using thermal or mechanical cutters. CNC cutting machines are preferred for precise cuts at this stage.

Siding Machines:

Siding machines process EPS or composite materials to produce decorative building facade details. The working principle is as follows:

Molding: The raw material is processed with steam or pressure in molds with specific patterns. During this process, decorative details are created.

Cutting: The molded products are precisely cut into desired sizes and shapes. CNC-controlled machines are often used at this stage.

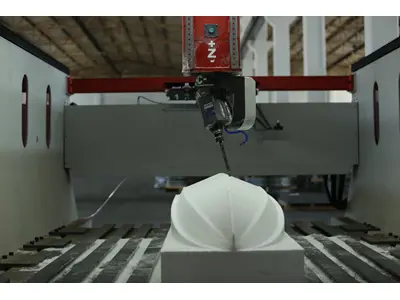

Detailing: Pattern adding or detail operations are performed on the products with milling machines.

In Which Sectors are EPS / Styrofoam and Siding Machines Used?

EPS / Styrofoam and siding machines contribute to both the architecture and construction sectors and the packaging and decoration industries, especially in critical areas such as energy efficiency, aesthetic design, and product protection.

EPS / Styrofoam Machines:

EPS and styrofoam machines are crucial for the production of lightweight and durable EPS products. The sectors where these machines are used include:

Construction and Insulation Sector: EPS sheets provide energy savings in the insulation of walls, roofs, and floors of buildings. With their lightweight and durable structure, they are used as decorative and protective cladding on building facades. EPS blocks are used as lightweight molds in concrete casting processes.

Packaging Sector: Product Protection: EPS is used as impact-absorbing packaging for transporting products such as electronic devices, delicate tools, and white goods. In cold chain and fresh food transportation, EPS boxes provide temperature control.

Decoration and Art Sector: EPS shaping machines are used for architectural models, sculptures, and various decorative embellishments.

Siding Machines:

Siding machines are designed to produce decorative building facade elements. The sectors where these machines are used:

Construction Sector: Used in the production of window and door surrounds, columns, corners, and other decorative details of building facades, as well as in the restoration and replication of facade details of historic buildings.

Decoration and Architectural Design: Used to produce decorative embellishments for interior and exterior spaces, as well as to produce detailed scale models for architectural projects.

Theater and Stage Decor: Siding machines specially designed for stage and theater decors are used to produce stage sets and decorative elements, creating visually stunning scenes for live performances.

Hotel and Restaurant Decoration: Luxury hotels, restaurants, and entertainment venues can have special and impressive interior decorations with siding machines. Custom-designed siding elements enhance the ambiance and atmosphere of the venues.

How to Maintain EPS / Styrofoam and Siding Machines?

Regular maintenance is necessary for the efficient operation and long life of EPS (Styrofoam) and siding machines.

Regular Cleaning and Disinfection: After production, regular cleaning is essential to prevent residues from accumulating in the machine. Pay attention to dusting electronic components and control panels.

Mold Inspection and Maintenance: Regularly check for deformations or wear on the molds. Protect the molds from rust and replace them when necessary.

Cleaning and Replacement of Filters: Regularly check the steam and air filters for clogging and dirt. Optimize the performance of the machines by ensuring the cleanliness of the filters.

Maintenance of Cutting Tools: Regularly check the blades of cutting machines and replace them when necessary. Worn or dull blades can affect product quality, so do not neglect the maintenance of cutting tools.

Lubrication of Moving Parts: Perform periodic lubrication of all moving parts in the machines. Lubrication enhances the performance of the machines and reduces wear and tear.

Is Environmentally Friendly Production Possible with EPS / Styrofoam and Siding Machines?

It is possible to achieve environmentally friendly production with EPS / Styrofoam and siding machines. EPS (Expanded Polystyrene) can be an eco-friendly material when used correctly and allows for the sustainable processing of this material. However, to achieve this goal, both manufacturers and businesses need to increase their environmental awareness and make continuous efforts to reduce environmental impacts.

What are the Prices of EPS / Styrofoam and Siding Machines?

The prices of EPS / Styrofoam and siding machines are generally diverse and depend on many factors. These factors include machine type, capacity, brand, technical specifications, and additional features. Additionally, prices can vary depending on the seller and manufacturer. For example, an EPS expansion machine can be sold at prices ranging from low thousands to high tens of thousands, while a CNC-controlled EPS cutting machine can cost much higher. EPS / Styrofoam and siding machines can have average prices in the range of {price range}.

EPS / Styrofoam and siding machines are large-scale equipment that require investment, but they generally deserve this investment for the productivity and production quality they provide in the long run. Additionally, the price of machines can vary according to the needs and budget of users.

To meet your needs for new or second-hand EPS / Styrofoam and siding machines, you can purchase from reliable manufacturers or authorized suppliers through makinaturkiye.com and also get support from authorized services.