DS 850 1000 Rotary Basket Washing Machines Wtih Shock Absorber Manuel Opening / Video

Rotary Basket Washing Machines Wtih Shock Absorber Manuel Opening

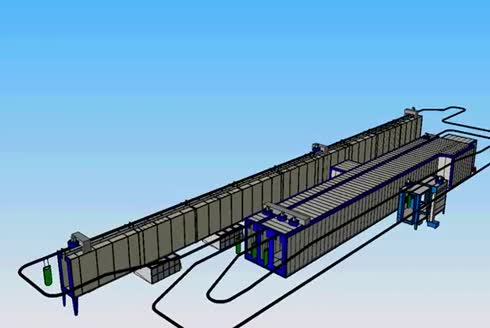

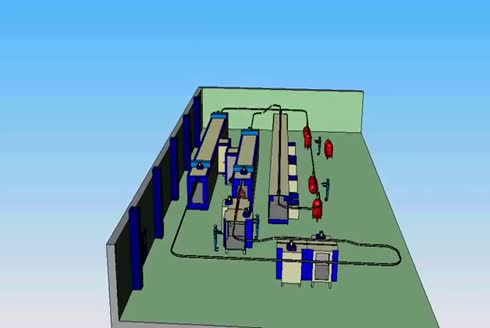

The Wespy DS-1000 Rotary Basket Washing Machine is a high-performance cleaning solution designed to remove tough contaminants like oil, sawdust, dirt, and other industrial waste from parts of various sizes. Featuring a stainless steel rotating basket, shock absorber manual opening, and high-pressure washing, this machine offers precise cleaning with minimal resource consumption. Ideal for industries that require efficient and eco-friendly cleaning, the DS-1000 ensures effective results while lowering operational costs.

Stainless Steel Rotative Basket: Parts are securely placed on a durable stainless steel rotating basket that spins during the washing process. This ensures that all surfaces of the parts are exposed to high-pressure water and degreaser from multiple angles, delivering thorough cleaning.

Shock Absorber Manual Opening: The DS-1000 comes with a shock absorber system that facilitates smooth and controlled manual opening of the washing chamber. This feature allows for easy and safe loading and unloading of parts, enhancing operational efficiency and safety.

High-Pressure Washing: The machine uses high-pressure water mixed with degreaser to remove oils, grease, sawdust, dirt, and other contaminants from the surfaces of parts. The pressurized water ensures effective cleaning, even for stubborn residues.

Adjustable Water Nozzles: Equipped with time-adjusted, pressurized water nozzles, the DS-1000 allows for customized cleaning according to the structure and pollution level of the parts. The adjustable nozzles ensure optimal water distribution for various part sizes and contamination types.

Recirculation and Filtration System: The DS-1000 is designed with a recirculation and filtration system that continuously filters and reuses water during the cleaning process. This reduces the need for fresh water and detergent, lowering operational costs and making the machine environmentally friendly.

Efficient Cleaning Process: The combination of high-pressure washing, adjustable nozzles, and recirculation ensures fast, efficient cleaning while using minimal resources such as water, detergent, and electricity.

Durable Construction: Built with high-quality stainless steel, the DS-1000 is designed for long-lasting performance in industrial environments. Its robust construction ensures reliability and reduces maintenance requirements.

User-Friendly Control Panel: The machine is equipped with an intuitive control panel that allows operators to easily adjust cleaning parameters such as wash time, pressure, and nozzle angles, ensuring that parts are cleaned according to their specific requirements.

Thorough Cleaning: The rotating basket and high-pressure water system ensure that all surfaces of the parts are cleaned from multiple angles, providing thorough removal of oils, dirt, and residues.

Cost-Effective: The recirculation system reduces water, detergent, and energy consumption, leading to lower operational costs over time. The system also decreases the need for frequent replenishment of cleaning agents.

Time-Saving: High-pressure cleaning with adjustable nozzles provides quick and effective results, reducing cycle times and increasing throughput. The shock absorber manual opening also speeds up the loading and unloading process.

Eco-Friendly: The filtration and recirculation system minimizes water waste, making the DS-1000 a more sustainable option for industrial cleaning applications.

Enhanced Safety: The shock absorber system ensures smooth and safe operation when opening the washing chamber, preventing accidents during loading and unloading.

Versatile Applications: The DS-1000 is versatile and can be used to clean a wide range of parts from various industries, including automotive, aerospace, manufacturing, and more.

Low Maintenance: The durable design and robust construction of the DS-1000 reduce wear and tear, resulting in lower maintenance costs and a longer lifespan for the machine.

Automotive Industry: Perfect for cleaning engine parts, metal brackets, and other automotive components that require removal of oils, grease, and other contaminants.

Heavy Machinery: Ideal for cleaning industrial machinery and equipment parts that accumulate dirt, grease, and residues during operations.

Aerospace Industry: Ensures thorough cleaning of aerospace components that require high cleanliness standards to ensure safety and performance.

Electronics Manufacturing: Suitable for cleaning delicate electronic parts where precision cleaning is critical for assembly and function.

General Manufacturing: The DS-1000 can clean a wide range of components used in various industrial sectors, ensuring optimal cleanliness and functionality.

The Wespy DS-1000 Rotary Basket Washing Machine with Shock Absorber Manual Opening is an efficient, eco-friendly, and cost-effective solution for high-pressure parts cleaning. With its durable construction, adjustable washing parameters, and recirculation system, the DS-1000 ensures effective cleaning while minimizing resource consumption. This machine is ideal for industries that require fast, reliable, and sustainable cleaning, offering a high level of versatility and performance.